Respiratory

Showing 1–16 of 33 results

-

JSP M632 Moulded Disposable Respirator FFP3 Box 10

Call for Price View Product -

Sundstrom SR221 Pre Filter (pack of 5)

£2.38 Ex.VAT View Product -

UCFD-P2V Disposable Valved FFP2 Cup Mask Box 10

£9.95 Ex.VAT View Product -

Sundström SR 510 P3 Particulate Filter (Each)

£9.95 Ex.VAT View Product -

3M 5935 P3R Particluate Filter for 6000 Series (Pair)

£11.00 Ex.VAT View Product -

Moldex 9030 P3 Particulate Filters for 7000 & 9000 Series Masks

£12.25 Ex.VAT View Product -

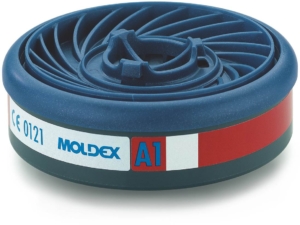

Moldex 9100 A1 Gas and Vapour Filter (pair)

£13.96 Ex.VAT View Product -

UCFD-P3V FFP3 Fold Flat Face Mask – Valved Box of 10

£15.50 Ex.VAT View Product -

Moldex 9200 A2 Gas & Vapour Filters

£16.12 Ex.VAT View Product -

Moldex 9300 ABE1 gas and Vapour Filter (pair)

£16.90 Ex.VAT View Product -

Fold Flat Tri Fold Disposable FFP3 Masks (Box of 10)

£17.26 Ex.VAT View Product -

3M 6000 Series Reusable Half Mask 6300 Large each

£17.55 Ex.VAT View Product -

3M 6000 Series Reusable Half Mask 6200 Medium each

£17.55 Ex.VAT View Product -

3M 6000 Series Reusable Half Mask 6100 Small each

£17.55 Ex.VAT View Product -

3M 6059 ABEK1 Gas & Vapour Combination Filters (pair)

£17.56 Ex.VAT View Product -

UC-P2V Disposable Valved FFP2 Cupped Mask Box of 20

£17.90 Ex.VAT View Product

Respiratory Protection Guide

Respiratory protective equipment plays a significant role in health and safety requirements for professions that are more likely to be exposed to respiratory risks.

It is worth mentioning that respiratory protection is not the same as COVID-19 masks worn during the pandemic to prevent the spread of the disease. Personal protective equipment includes respiratory protective equipment designed for the workplace.

This article focuses on the use of full face respirators and half face respirators that are used in the workplace as per the UK's regulations for safe work equipment. In this guide, Provincial Safety will explain the importance of respiratory protection in the UK. We will also introduce the different types of respirators available and the type of respiratory hazards British workers can face in the workplace. For clarity, this article does not expand on respiratory protection regulations outside the UK.

The Importance of Respiratory Protection

Experts estimate that over 12,000 deaths annually in the UK are linked to exposure to harmful substances in the workplace, such as chemicals and dusts. Indeed, breathing hazardous substances at work can significantly affect employees' health and lead to a vast range of health conditions such as asthma, lung cancers, and chronic obstructive pulmonary disease (COPD).

According to a national survey dating from 2010-2011, 31,000 individuals have reported suffering from lung or respiratory issues related to their work. Additionally, health specialists suspect that the deaths of approximately 4,000 individuals from COPD may be related to exposure to substances in the workplace.

Respiratory protective equipment is one of the different approaches available to employers to regulate breathing hazards. By order of effectiveness, the hierarchy of breathing hazard control includes:

- Eliminating the hazard

- Replacing the hazard with a less-harmful substance

- Providing engineering controls such as ventilation and automated processes to reduce risks

- Reducing risks through administrative controls such as training, safety signage, etc.

- Wearing respiratory protection

While respiratory protective equipment is the least effective approach, it remains a necessary step to provide workers when the risks can't be eliminated or mitigated. Employers must try to eliminate the source of the hazard first. Yet workers must wear RPE when all other control measures are not applicable or successful. It is important to note that RPE is the last resource to provide protection to the employees.

Respiratory Protective Equipment Regulations

Employers have the legal duty to protect breathing as per the UK's health and safety regulations.

The Health and Safety at Work Act 1974 places on employers the duty to prevent unnecessary health and safety risks as part of the work activities. The HSE website explains the basic information to keep businesses compliant with the health and safety law, including respiratory protective equipment.

The COSHH regulations (Control of Substances Hazardous to Health) from 2002 establish clear steps to prevent exposure to harmful substances, such as:

- Assessing the health risks from work activities

- Deciding on the relevant precautions and control measures

- Ensuring control measures are maintained

- Training and informing workers

- Providing health surveillance and monitoring exposure

The Control of Asbestos Regulations 2012 details the essential preventive steps, including respiratory protective equipment, to reduce asbestos exposure.

The HSE also states that health risks could be more significant for employees who have pre-existing health conditions; therefore, it is essential for employers to protect employees through:

- Appropriate training on how to use, store, and wear respiratory protective equipment

- Information and health assessments to ensure better protection

- RPE fit tests to ensure workers have the right protection for their needs

RPE used in the UK meets European standards of protection (EN). Different standards apply depending on the types of respirators and the level of exposure.

Indeed, the EN136 standard, for instance, applies to full face respirators and can be categorised into three classes (1, 2, 3) depending on the level of durability and protection required.

EN140 and EN149 apply to half face respirators. Respirator filters must also meet requirements based on use and protection levels, ranging from P1 to P3.

Where Is Respiratory Protective Equipment Needed?

The type of respirators required will depend on the workplace and environmental exposure to hazards. Employers are required to perform full risk assessments before deciding whether RPE is necessary and which protection will be the most effective.

When the presence of hazardous substances can be mitigated, both half face respirators and full face respirators may be necessary to protect employees from risks.

Exposure To Dust

Thin fibres in the air, such as glass wool and asbestos fibres, count as dust exposure. Additionally, wood dust, cement dust, and silica dust from stone can also affect employees' health.

Dust exposure is a frequent risk in the construction sector, whether in new buildings, remodelling projects or renovation and repair in existing buildings. Powdered chemicals such as cement can find their way to the lungs without adequate protection.

Engine work, such as mechanics, can also expose employees to dust, from the exhaust, for example.

Fumes

Metal work can create potentially harmful fumes through burning metals, soldering and welding.

Gas

Gas is often associated with laboratory workplaces. But they can also arise from solid being combined with moisture, such as phosphide, which can give off phenol vapours.

Vapours

Paint, petrol, solvent, thinner, and varnish can produce harmful vapours. Additionally, sprays and mists such as paint spraying or battery acid mists can be dangerous substances.

Type of Respirators

Different types of respirators will be needed to provide adequate protection depending on the work environment.

Unpowered respirators essentially draw the air through a filter cartridge. The filtering face piece (FFP) tends to be a half face respirator that removes solid particles. FFP respirators are difficult to seal around the face and are not suitable for prolonged use.

On the other hand, powered air respirators are full face respirators that use a battery and blower unit to create a safe breathing atmosphere. They can last for several hours on battery and are best suited to filter chemicals and dust during prolonged exposure. They are fitter with different respirator filters depending on requirements.

Air-fed respirators are similar to full face powered respirators, but they are hooked to a compressed air system rather than using a battery and blower unit. This can reduce motion but can be highly effective to keep the air breathable in environments exposed to gas contaminants.

Finally, visor respirators are full face respirators best suited to prevent metal fumes when welding.

At Provincial Safety, we specialise in health and safety equipment for the workplace. Our range of respirators includes reusable powered air respirators, unique respirator filters, and disposable half face respirators. We believe that the right protection equipment can save lives and hassles in the workplace.

If you have any questions, or require guidance on which products you should invest in for your construction team, contact a member of our highly-experienced and friendly team today on +44(0)121 544 5208 or by emailing sales@provincialsafety.co.uk.